We will assume that we are planning to open a chain of high-end coffee shops. We want to understand better how the supply chain will evolve as we grow.

We will proceed in three steps:

For the purpose of this example we will assume that we start from scratch without any existing investments in warehouses. We will also make assumptions about future revenues and costs.

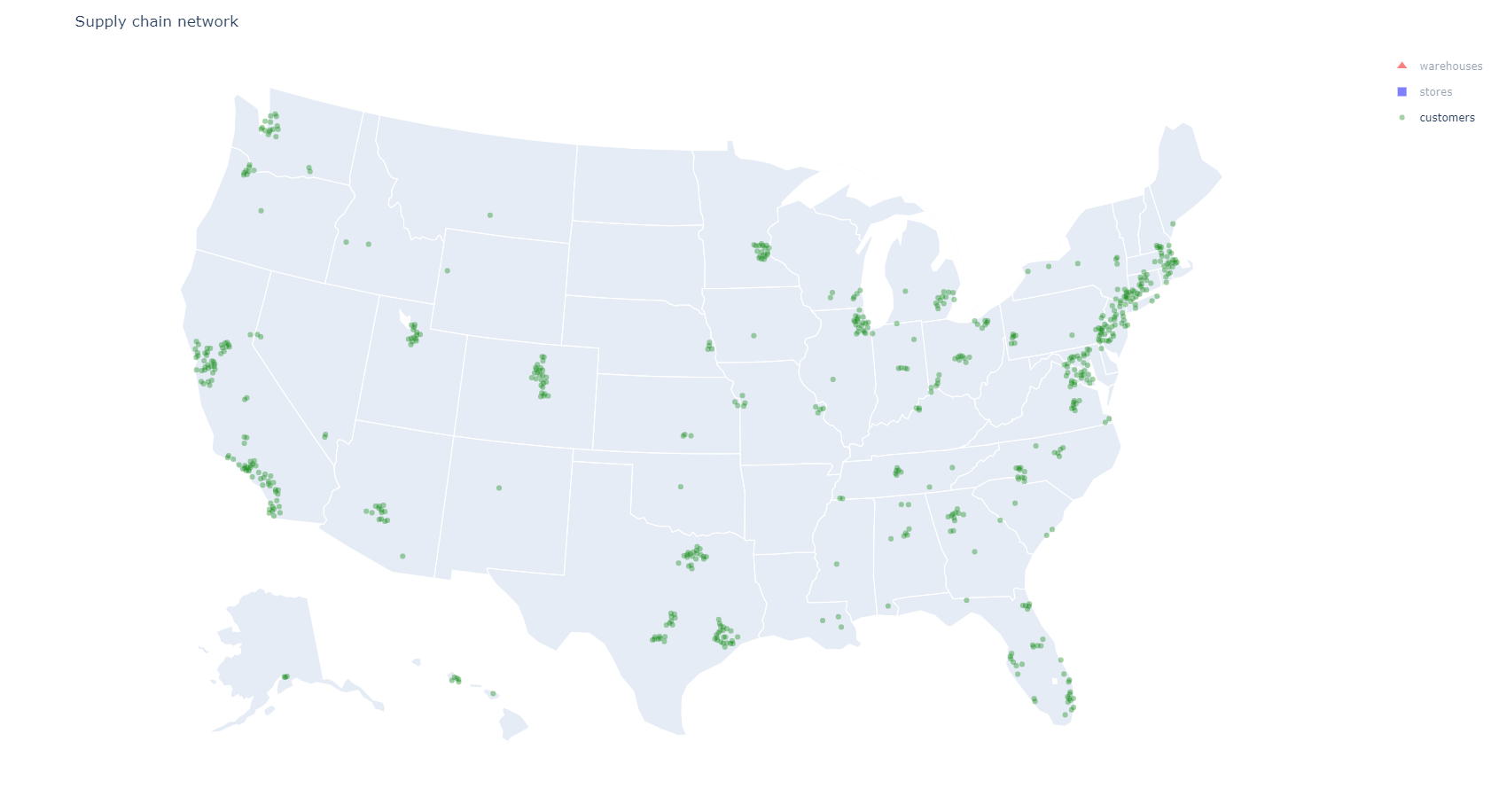

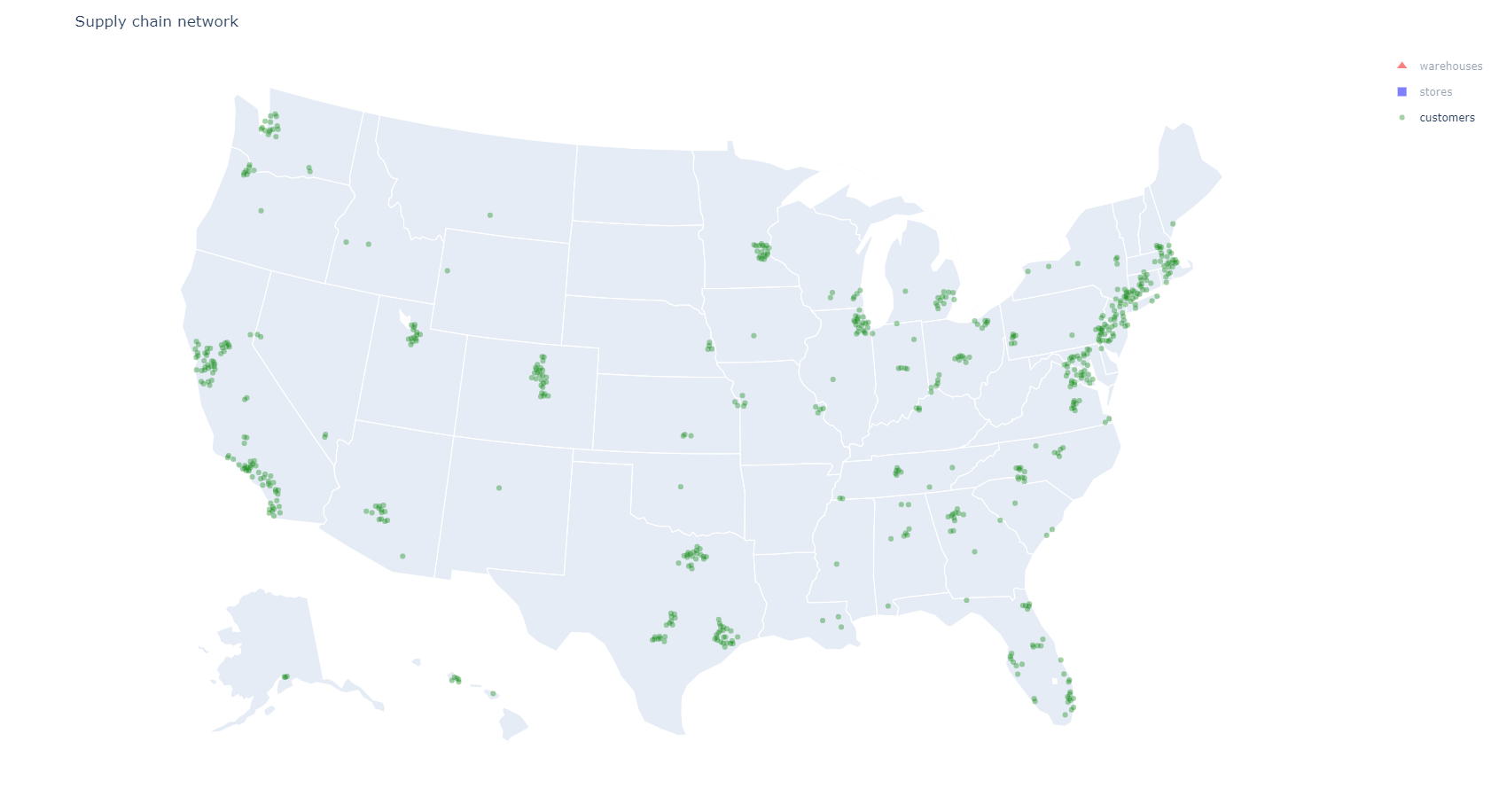

Since we are opening a chain of high-end coffee shops we expect that our customers will be fairly well off. We will use data from the US census to identify zip codes where people have higher than average earnings. This is of course just an approximation of where our customers may be. There are other places we could think of: work places, airports, fancy resorts. Your marketing department may have a list available for you. Our esimate will be good enough for now.

Once we know where to find our customers, we will need to estimate how much they will spend. We will again make some assumptions and, based on competitive information, we will estimate that a store can generate about $1,000,000 in revenues per year per 4,000 customers (each customer spends about $250 a year, or about 1 lattes a week at $5 each).

Now that we have a better understanding of the customers, let's look at the supply side. We will start with our assumptions about our stores.

Because we plan to open coffee shops we expect the stores to be very close to customers. If we had opened other types of stores (e.g., grocery, home improvement, speciality) we would expect customers to drive further and have a bigger catchment area. If we had operated an e-commerce website we would expect to ship directly from warehouses and have an even bigger catchment area. All these options can be modeled to match your specific situation.

From our competitive analysis we estimate the following costs:For each warehouse we want to operate, we estimate that the fixed costs will be around $10,000,000 a year. We want to limit risks if a warehouse has operational problems so we limit to 600 the number of stores that a single warehouse can serve. Again, these numbers are just to get us going. We could refine them by speaking to providers and operators.

As far as location is concerned, we will look at locations with easily available and cheap(er) workforce. We will again identify these places with census data.

With all the data we have collected we can know invoke the SupplyChops solver to compute the ideal network. One thing to note: because we look for long term maximum profitability we ignore the opening costs of facilities. These costs will wash away in the long term compared to recurring costs and revenues. We will see below how to consider them when planning our supply chain network transformation.

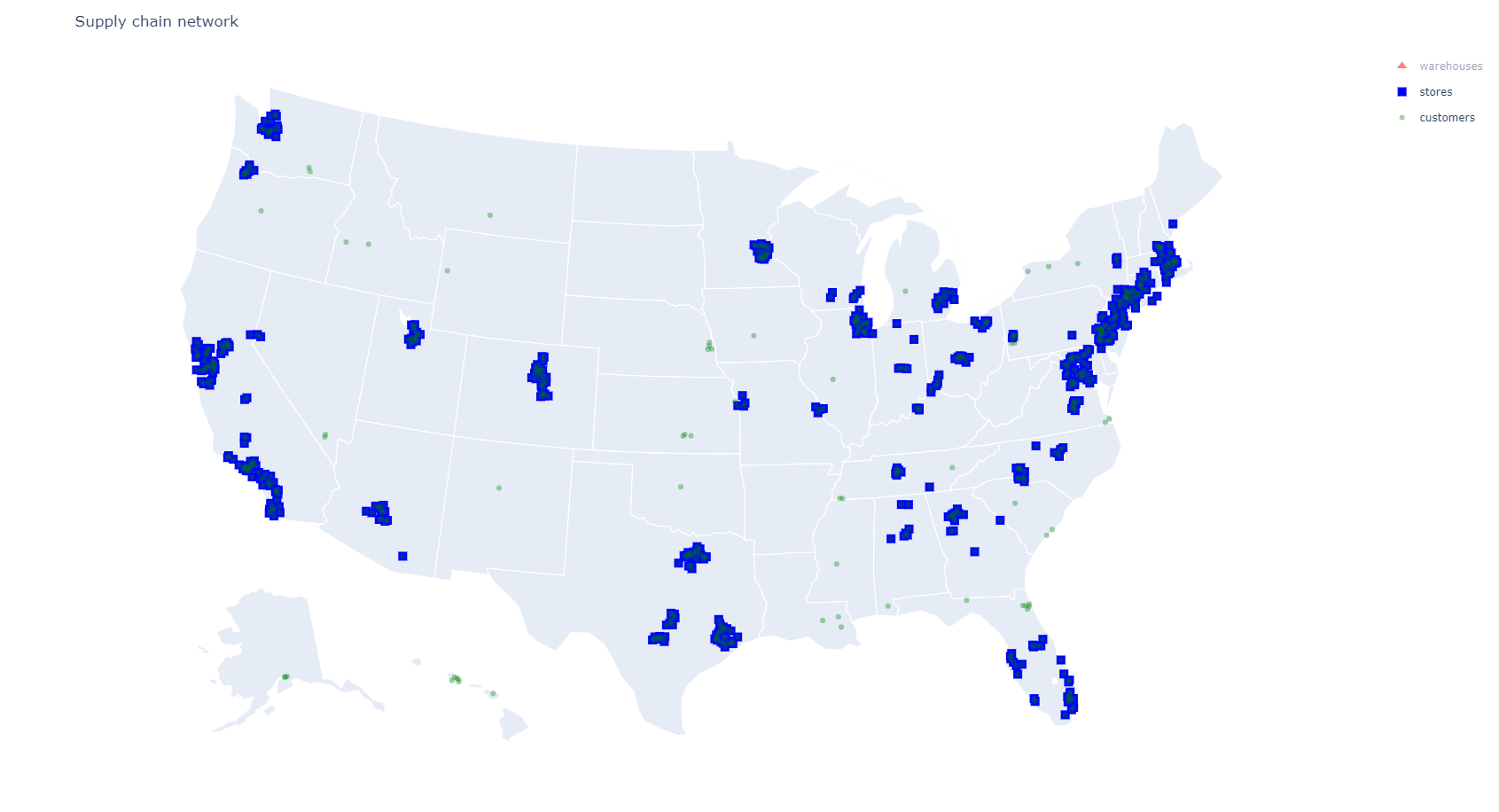

Let's first consider where to locate the stores. The map below shows the store locations. We operate 10,888 stores that cover the majority of the big population centers.

We should not a difference with a typical supply chain network analysis: not all potential customers are covered (green dots with no blue dots).

Out of a total market of 11396 potential stores we cover 10,888 or just above 95%. This is by design, and this is beneficial. With the current financial assumptions, serving these customers would

We will revisit the unserved customers later in this page.

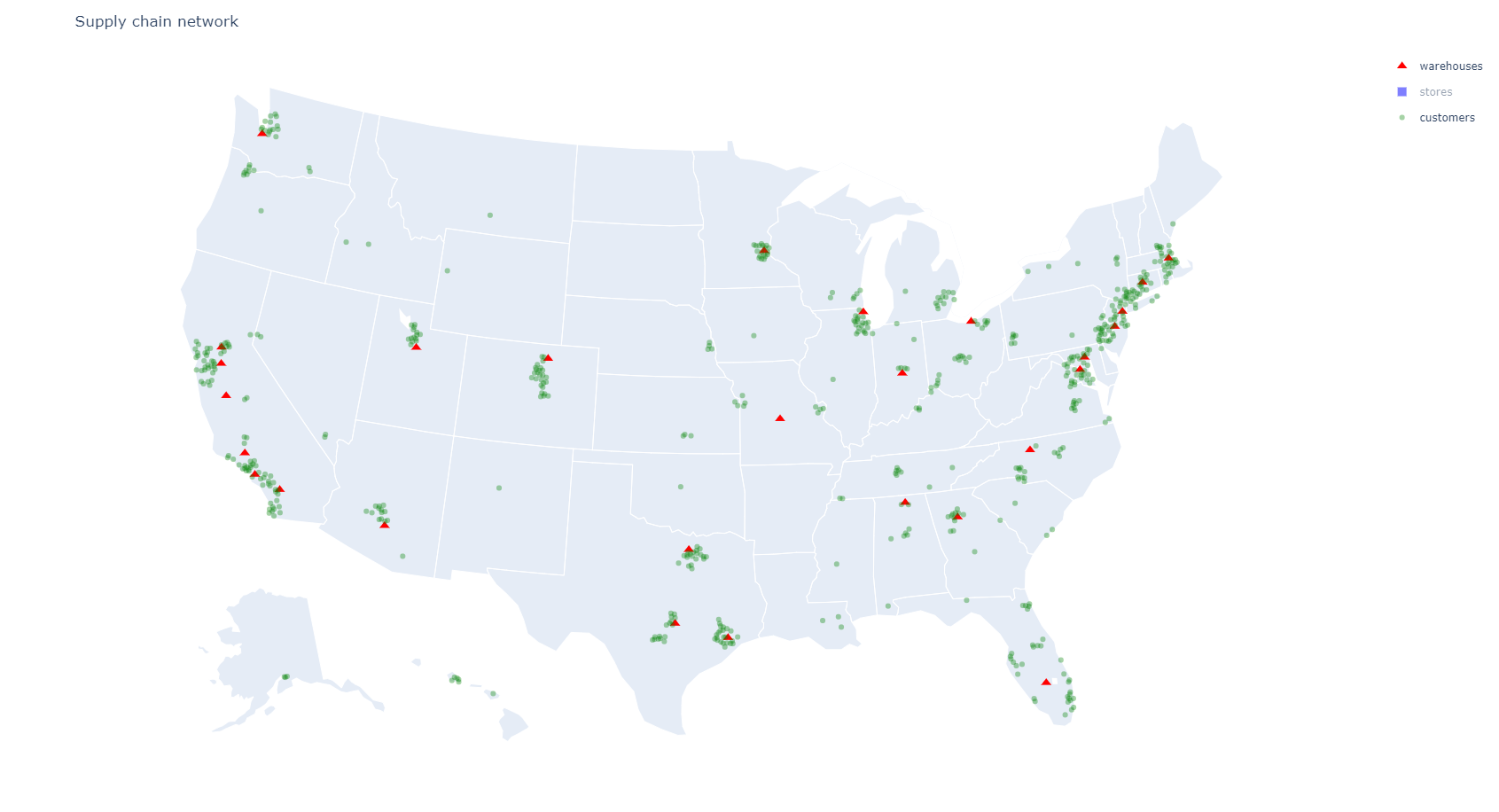

We can also look at the locations of our warehouses. These are shown on the map below. There is little surprise there. The warehouses are located near the stores. For bigger markets, we need several nearby warehouses because a single warehouse would need to support more stores than the limit we imposed. For smaller markets, a single warehouse may support several markets.

Now that we have our ideal network, the next question is how to transform our supply chain from its current state to its ideal state. For this use case we assume that we start from scratch. We do not have any stores or any warehouses yet. We will discuss transforming an existing supply chain later in this section.

Assuming that our ideal network is profitable, the best plan is to immediately create that network. It is the most profitable so the quicker we transition to it, the more money we will make. The problem of course is that we don't have the resources to open more than 10,000 stores and all the warehouses all at once. We don't have the capital nor the people to do so. So, what should we do?

We will assume that we have access to 300 millions of financing. After that we will need to grow organically and to start showing profits. These are strong constraints given the costs of opening stores and warehouses. Of course your specific situation will be different but we all need to have a budget.

With our budget constraints in place we will model the supply chain transformation for the next 10 years.

Because we are now looking at the timing of specific investments, the opening costs become important. We estimate that the opening costs of a new warehouse is $20,000,000 and the opening costs of a new store is $1,000,000.

The movie below shows how the network grows: we open one warehouse at a time, then open more and more stores until we saturate each market as we go along. The network grows about 14% year over year.

We should note that there are other similar plans with similar profit profiles. They differ in the markets they open first. When doing a network analysis it is important to not only look at the 'best' plan but also close seconds. It could be that factors that have not be modeled would tip the balance in their favor (and of course, it is a sign that we need to add these factors to the model).

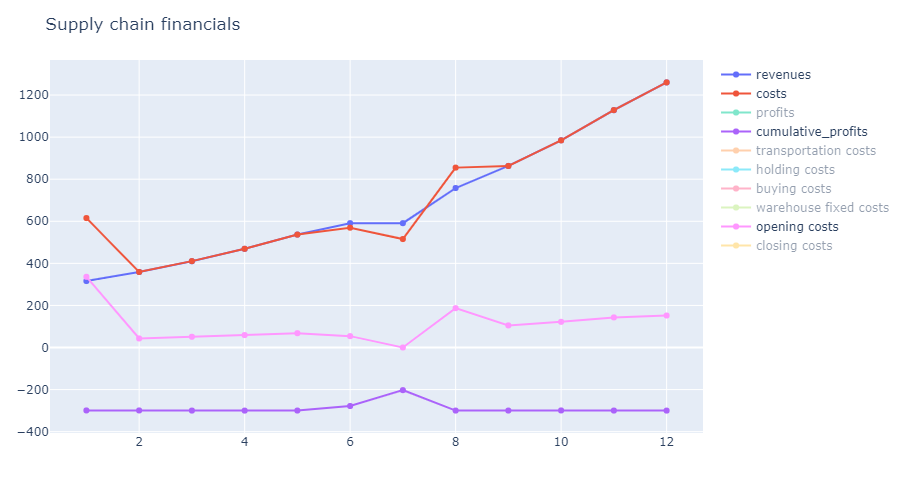

The financial results of the transformation plan are plotted on the following graph. We can see the initial investment and then the switch profitable growth. The capex (store and warehouse opening) and the opex (store operations, product purchase, transportation) are all broken out.

We see that in year 7 the growth is paused. This enables the company to accumulate resources that it spends in year 8 to build a new warehouse.

We saw in the graph above that not all customers are served. Some are unprofitable and it is better to not serve them. However having unserved customers should be a signal for deeper thinking.

Here are some ideas:

We can be inventive and model the consequences of our ideas.

If nothing else works, we can force SupplyChops to serve the customers no matter the profitability by setting a service level of 100%. In this case SupplyChops will serve them as long as there is a feasible way to do so while minimizing the losses.

Performing a traditional supply chain network analysis is time consumming. We need to understand the costs of operating warehouses, the costs of transporting goods, the costs of buying goods. We need this information for existing warehouses and transportation lanes, and we need this information for potential warehouses and transportation lanes.

We add another level of data here: understanding the potential revenues from customers and the costs of servicing them with stores.

The question is: is the additional work woth it?

Let's look at some alternatives

Creating an ideal profit-maximizing supply chain is hard work. SupplyChops can help you make this journey more productive.

Which supply chain leader do you want to be?